Experience the new standard for 3DP microfluidic devices with Ergometa

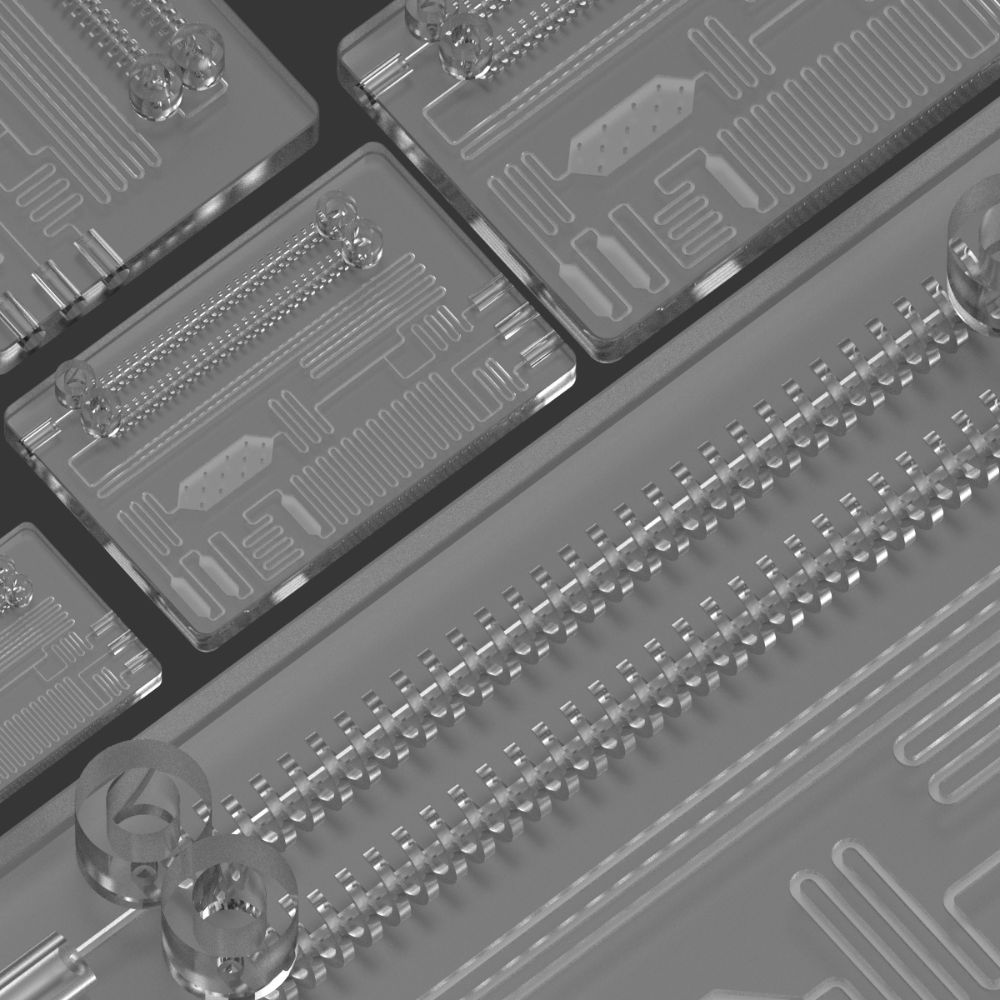

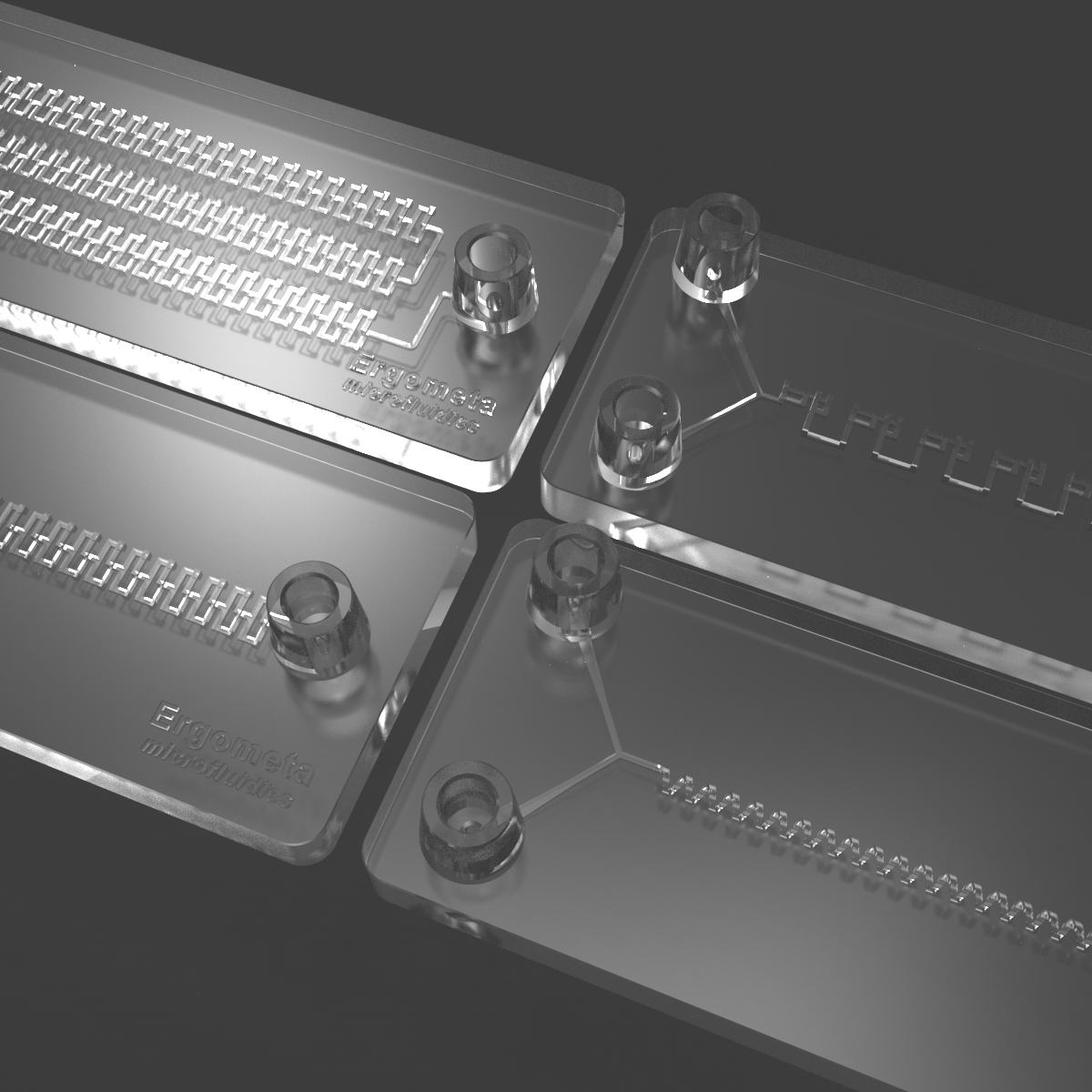

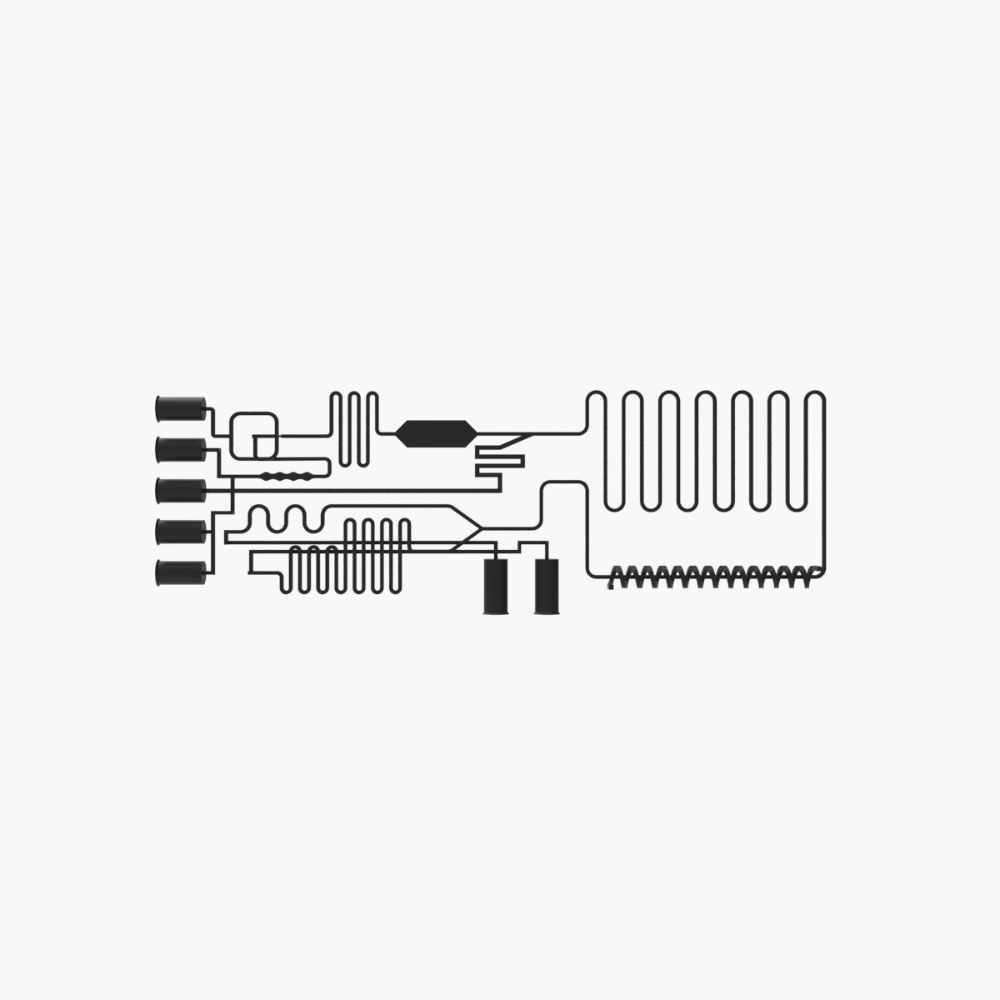

Micromixers

A micromixer is a device that utilizes small-scale fluid

dynamics to efficiently and rapidly mix fluids, enabling

precise control and uniformity in mixing applications.

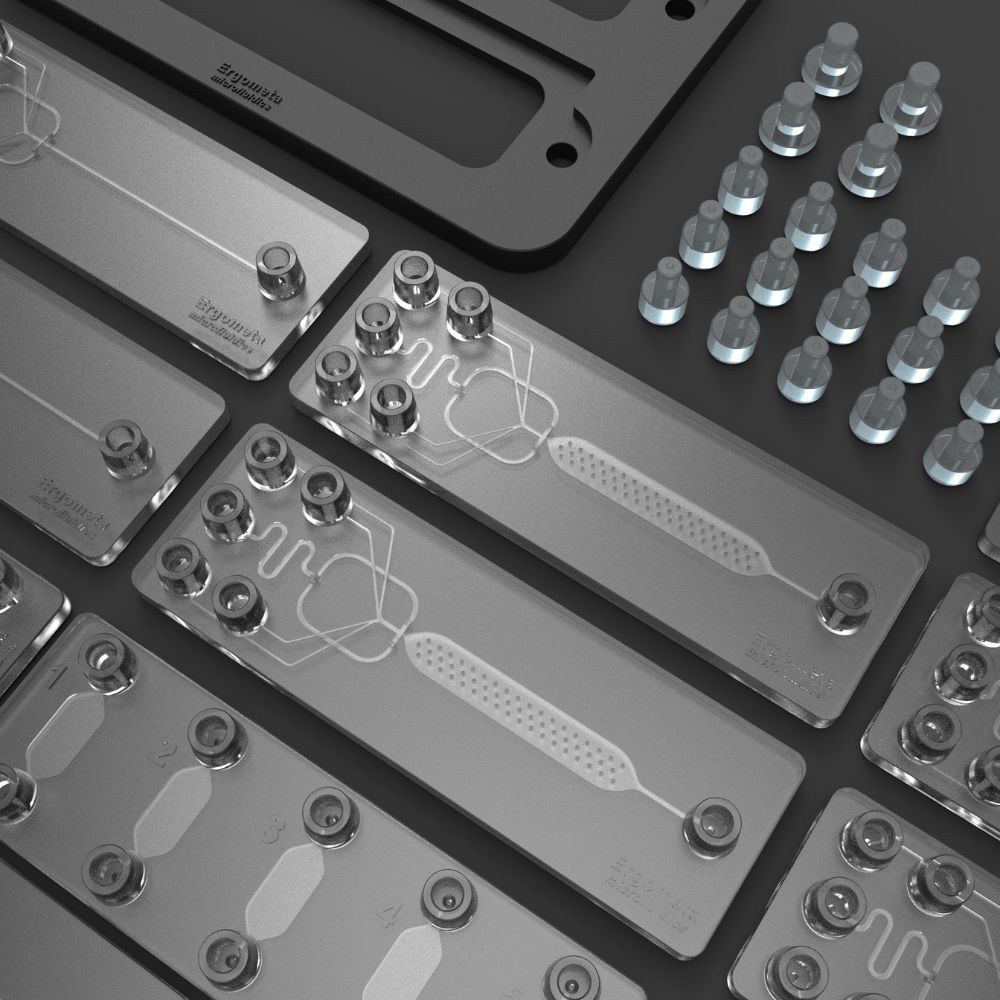

Droplets generators

A microfluidic droplet generator is a device that uses microscale channels to precisely control the formation and manipulation of tiny droplets, enabling applications in biomedical, chemical, and materials research.

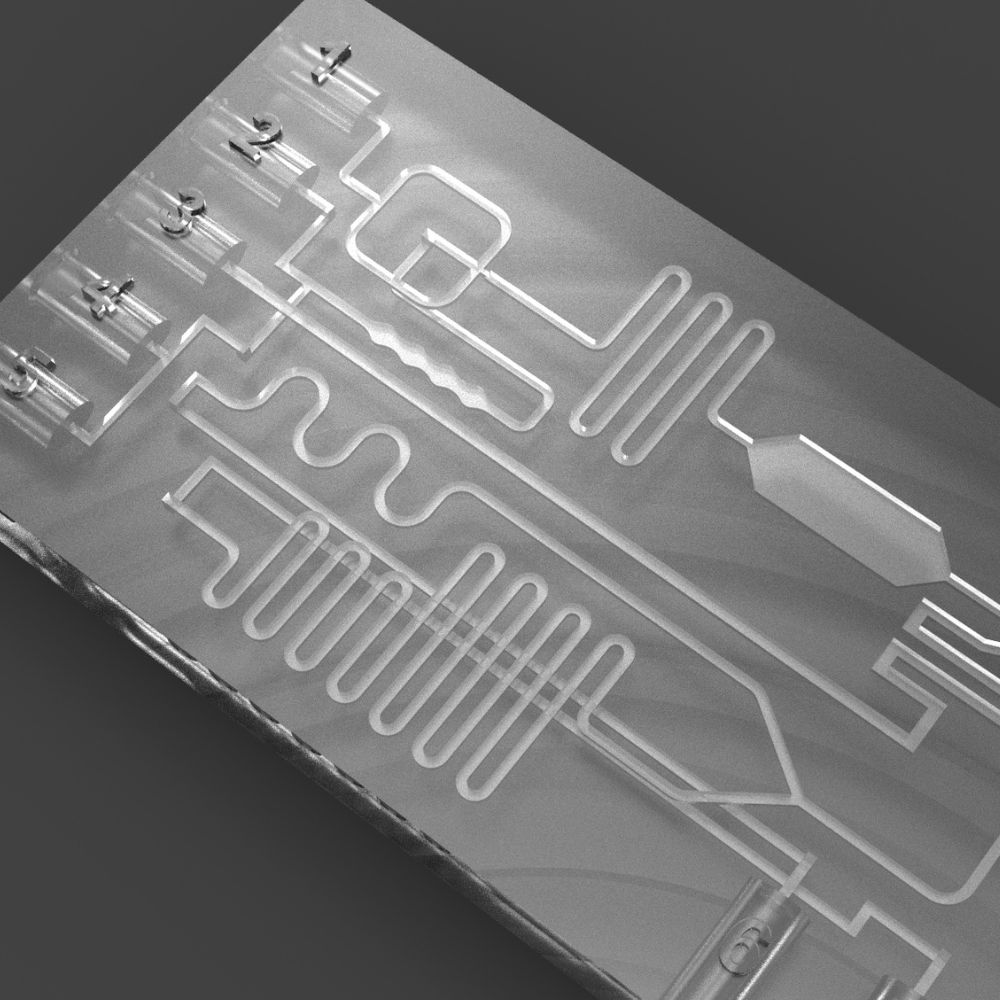

Lab-on-a-chip

A lab-on-a-chip is a miniaturized device that integrates multiple laboratory functions onto a single chip, enabling precise control and analysis of fluids for various scientific and diagnostic applications.

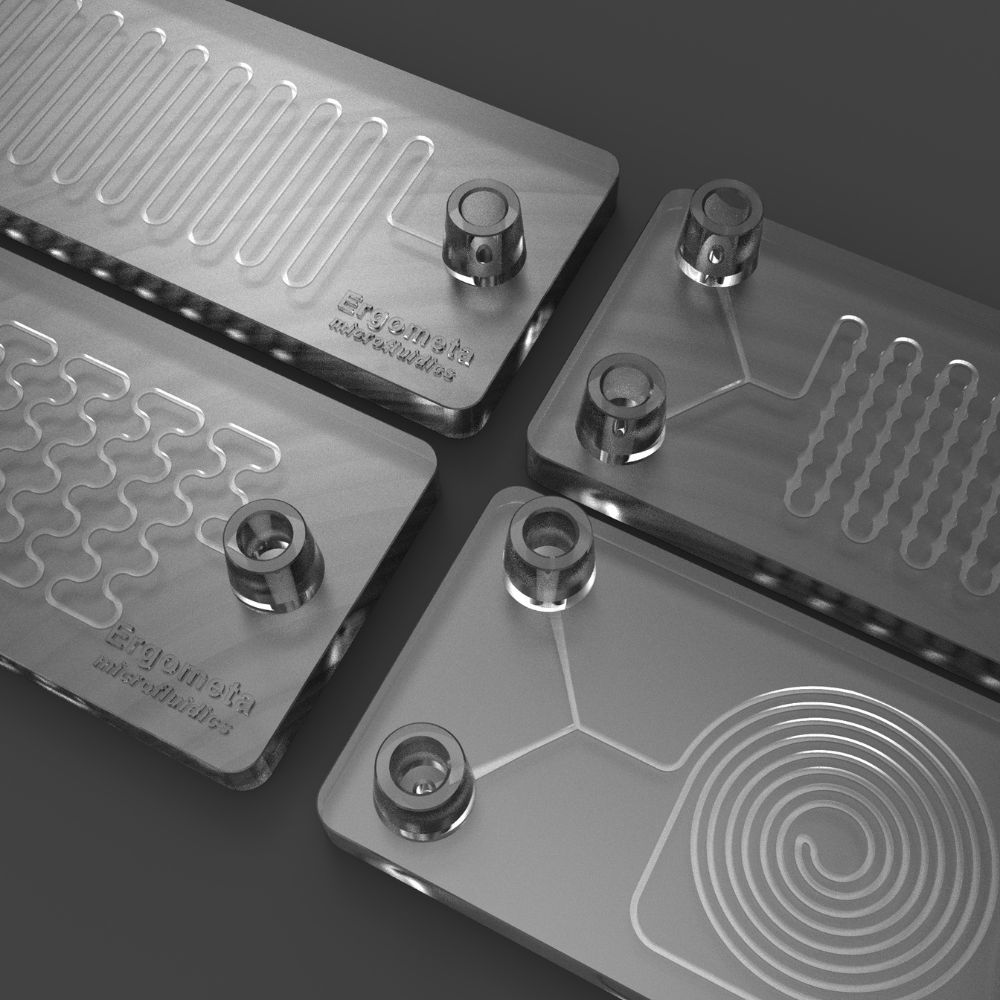

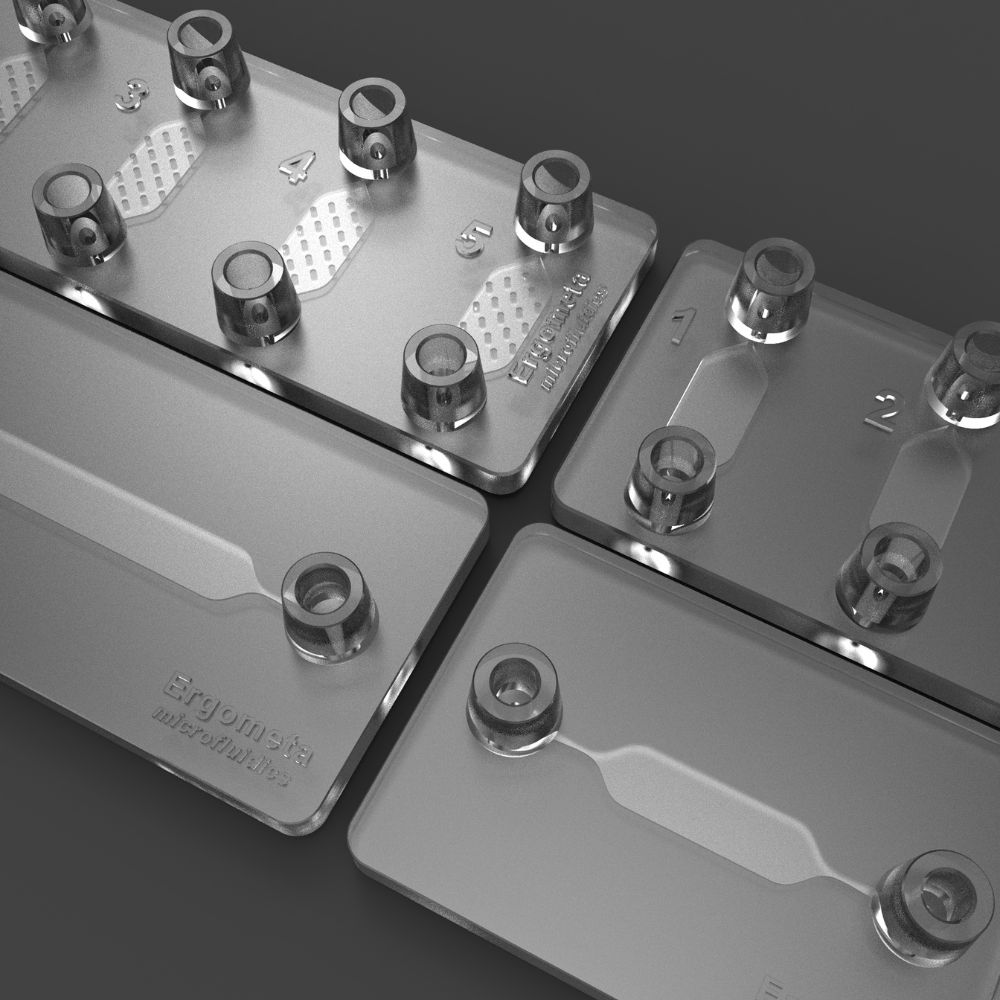

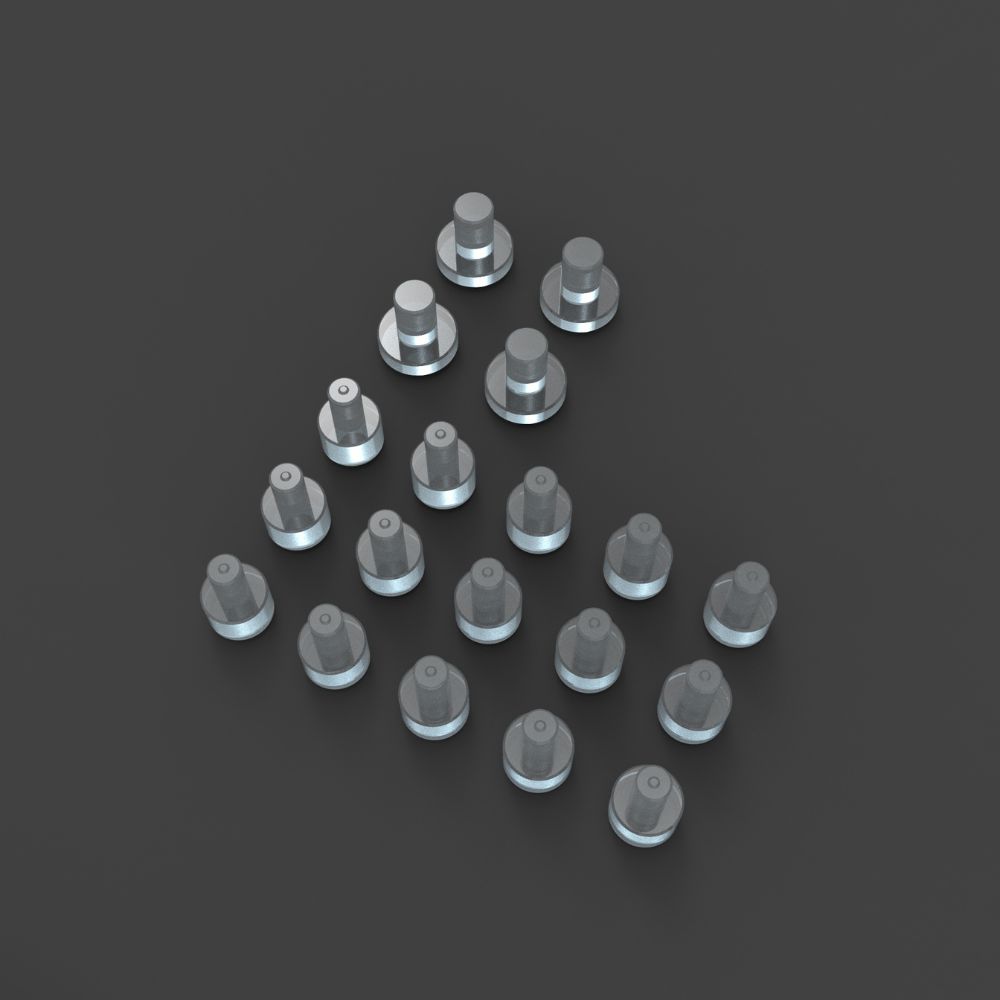

Microfluidics starting kits

Our notable microfluidics partners

Asiga MAX X UV

Flexible precision. The MAX X is Asiga's highest definition 3D printer with a re-configurable resolution of 27, 35 or 43 microns.

Why choose an Asiga printer for microfluidics?

Precise

In microfluidics manufacturing, extreme accuracy and precision is required. The Asiga MAX X has a pixel resolution of 27µm, 35µm, or 43µm. Parts with capillary tubes, nano-pumps, or channels for micro wiring are being printing on Asiga MAX Xs every day.

Easy to Use

Asiga’s additive manufacturing systems are designed as plug and play right out of the box. Composer software imports STL or SLC files that are a common export file from most CAD programs on the market. It’s just that easy.

Accurate

Asiga's unique SPS™ process guarantees every layer is formed accurately. Accurate layer formation is the key to achieving consistently accurate results in any application especially microfluidics.

Open

All Asiga systems are open material systems, allowing build materials from most manufacturers designed for DLP systems to be used. Biocompatible and engineering resins from a range of manufacturers are currently being used with the Asiga Systems.

Affordable

Amazingly low prices for leading edge, well-engineered, 3D additive manufacturing systems.

Custom solution consultation request

Microfluidics is the science and technology of manipulating fluids in functional components with structures ranging from a few micrometers to millimeters (According to G. Whitesides [1]).

Today, in the field of life sciences or diagnostics (especially molecular diagnostics), almost no product is being developed that does not contain elements with some form of microfluidic functionality. The physical principle or scaling law underlying his development is Fick's law of diffusion [2]:

t = l2/D

Here t is the diffusion time, D is the diffusion coefficient and l is the distance between the molecules. Ifl is now reduced (say by a factor of 10) due to the miniaturization of the structure in which these molecules are contained, the diffusion time is reduced by a factor of 100! At the same time, this reduction in scale would create more reaction sites per unit area, which would further increase the possible information density [3].

[1] Whitesides, G., The origins and the future of microfluidics, Nature, 442, 368-373, 2006

[2] Fick, A., Ueber Diffusion, Ann. Phys. 170(1), 59-86, 1855

[3] Janasek, D., Franzke, J., Manz, A., Scaling and the design of miniaturized chemical-analysis systems, Nature, 442, 374-380, 2006

Historically, microfluidics and its use as a lab-on-a-chip for applications in life and analytical sciences began with technologies available in the semiconductor industry. As a result, these technologies were used in the first microfluidic devices because they were available and could be microstructured. The materials that could be configured with the technologies used in the semiconductor industry were glass and silicon.

The first microfluidic devices, as well as inkjet print heads for microfluidics outside the life sciences, were made of glass and silicon and date back to Stephen Terry's gas chromatographs integrated on silicon wafersinthe1970s. The availability of such semiconductor fabrication technology at many engineering institutes has made these fields pioneers in microfluidics due to the availability of sophisticated but often expensive technology.

Microfluidics is an important tool for analytical chemistry and offers advantages in terms of reagent consumption, waste generation, process integration and cost. Current methods for manufacturing microfluidic devices include micromachining, micro-milling, hot embossing and injection molding, but these processes can be time-consuming, inaccurate, costly and difficult to modify designs. In addition, they often require a dust-free (clean room) environment to produce defect-free devices. In addition, microfluidic devices produced by conventional methods lack true three-dimensional (3D) architecture and flexibility in device design.

Finally, materials commonly used to fabricate microfluidic devices have disadvantages such as surface adsorption and solvent swelling of polydimethylsiloxane (PDMS)and gas impermeability and stiffness of thermoplastics such as polymethylmethacrylate(PMMA) and cyclic olefin copolymers. Microfluidics is an important and promising tool for performing many analyses, but the production of these devices is not yet ideal. There is a need for better manufacturing methods that allow iterative prototyping and production of microfluidic devices that are cheaper, easier and faster.

3D printing is a recently emerging technology for the production of microdevices.

3D printed designs can be easily edited and reprinted, allowing for test-based optimization. Furthermore, 3D printed devices do not require a clean room manufacturing environment. Finally, 3D printing must provide unique features as all three dimensions can be fully utilized in the construction of the device. [4]

[4] https://www.annualreviews.org/doi/10.1146/annurev-anchem-091619-102649

Ergometa’s R&D department has a broad range of expertise in rapid microfluidic prototyping and manufacturing of a functional devices.