Metal 3D Printing

Imagine being able to create components and objects out of metal regardless of shape or size. We are not referring to carving out of metal or welding existing pieces of metal together. We mean having a metal design formed for you, metal 3D printing. In the past, people would heat metal to high temperatures, then poured it into molds and cool it. Now, this can be done through additive manufacturing.

In additive manufacturing, material is being put together or added in order to create an object. This is in contrast to conventional manufacturing which removes material in the creation of an object (CNC machines, woodworking, sculpting, etc.). The advantage of additive manufacturing is that the design determines the manufacturing process. This is why it is often called "design for additive manufacturing" (DfAM). How does the process work? With metal, there are two ways: Laser Metal Fusion (LMF) and Laser Metal Deposition (LMD).

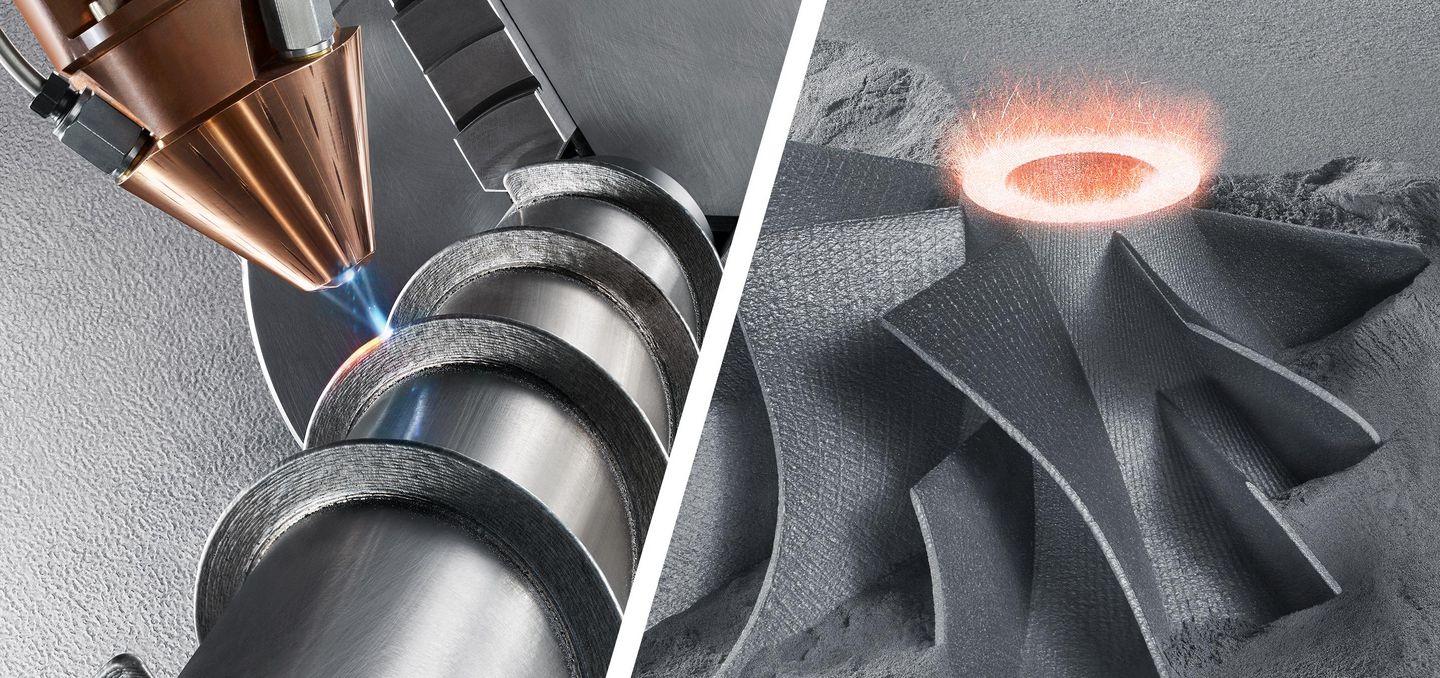

With LMF, a laser melts or sinters metallic powder according to a preprogrammed design. In other words, a person creates a 3D design within a program, sends it to a metal 3D laser printer and it builds the design for them creating a very stable lightweight metal structure.

With LMD, a laser heats up a piece of existing metal to create a weld pool and adds small metallic beads that are melted into the area of the weld pool. This process is good for repairing, adding to metal or coating metal with a very thin coat.

Ergometa is proud to provide Trumpf metal laser printers to the world. TRUMPF is a pioneer in additive manufacturing methods and have created a printer that can do both LMF and LMD printing. Turn to Ergometa for all your metal 3D printing needs.